Reports from our customers

User reports

Learn how different customers

use our software

CUSTOMER SUCCESS STORY

ERNST Umformtechnik

The design department of the German company ERNST Umformtechnik GmbH, situated in the town of Oberkirch, creates CAD models and drawings of forming tools for sheet metal processing. Tools are designed using the SolidEdge CAD system, and component tolerancing is carried out during the creation of the 2-D drawing. The 3-D models are read into a CAM system for programme creation.

to the Report

Customer Success Story

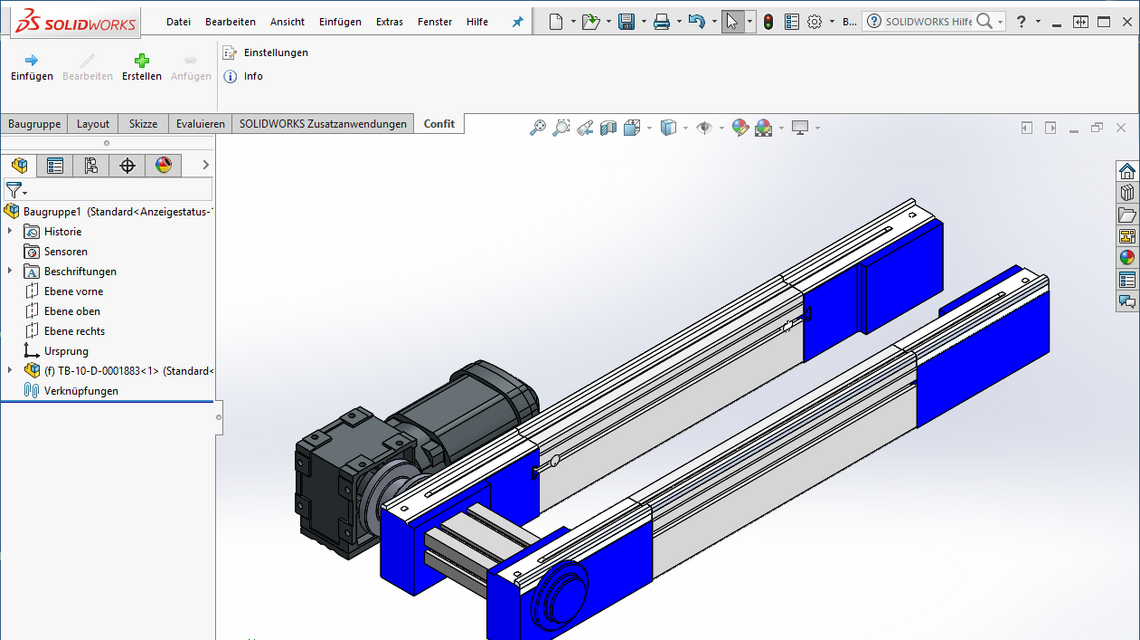

Confit bei Schnaithmann

Dozens of designers, hundreds of assemblies and parts and thousands of parameters. Read in our latest user report how Schnaithmann Maschinenbau GmbH got to grips with this multitude of variants using the CAD automation software Confit.

to the report

Customer Success Story

REVEN Web-based Configurator

The company Rentschler REVEN uses a cloud solution developed by REITEC for sales support and the provision of BIM data. The modern technology and the interactive user experience are particularly noteworthy. As always, REITEC was a reliable partner in the realisation of the project and the schedule was exceeded.

to the report

Customer Success Story

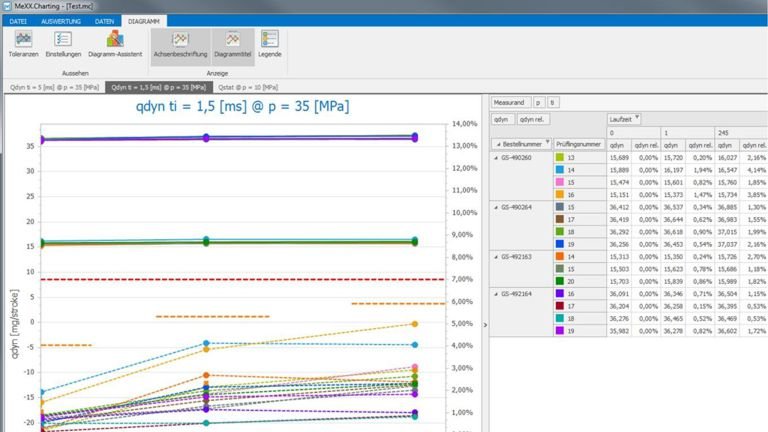

BOSCH Mobility Solutions

For the management of measurement and development data in injector development, BOSCH has been using the MeXX measurement data management system for many years. Around 150 users use the system at the Schwieberdingen site. Over the years, the system has been continuously developed and improved with numerous enhancements. With the latest extension, a module for the standardised generation of evaluations, the entire process of evaluating measurement data is optimised and accelerated.

to the report

Customer Success Story

August Berghaus

August Berghaus from Remscheid, one of the leading manufacturers of broaching tools, relies on REITEC technology for the management of its operating resources. The solution was developed and put into production within a very short time. The highlights of the application include: automatic calculation of the degree of wear, configurable interface, scanner support, customisable report templates and extensive search and filter functions.

to the report

Customer Success Story

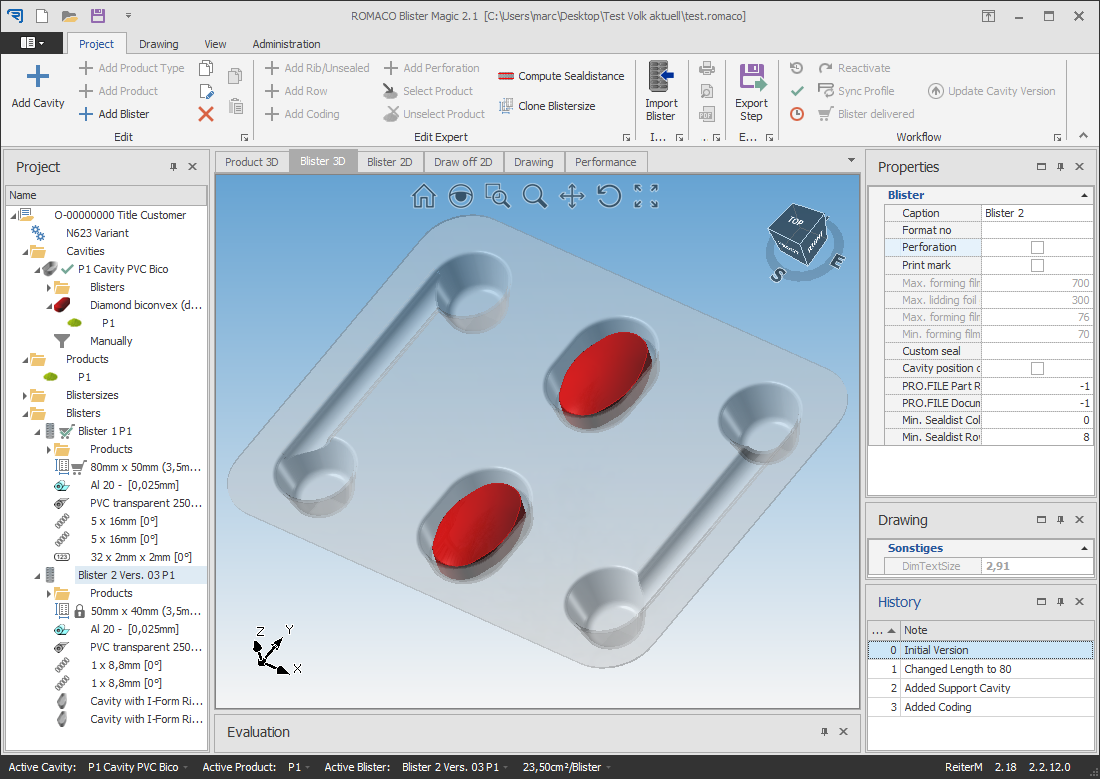

ROMACO

With the software developed by REITEC GmbH for the design of blister packs, the ROMACO company is able to react quickly and flexibly to the requests and requirements of its customers. The software works without an expensive and complex CAD system and supports the employees with assistants in their daily work. Realistic 3D representations of the blister packaging and high-quality 2D drawings create considerable added value for the customer. In addition, the software includes complete change management and numerous interfaces.

to the report

Customer Success Story

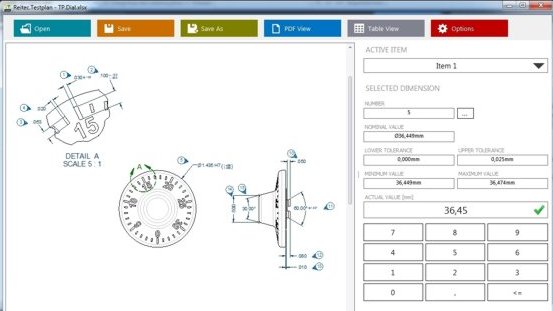

ASFO (Italy)

The company ASFO (Italy) relies on state-of-the-art technology in quality assurance. With the tablet-based software Reitec.Testplan developed by REITEC GmbH, the QA process is considerably simplified and accelerated. The QM employee can now record measured test dimensions directly in the tablet application and receives direct feedback as to whether the dimension is within the tolerances. Reitec.Testplan can directly load and edit the test plans created with the help of the CAD add-in Reitec.Testplan for Inventor. The dimensions are selected by tapping on the dimension in the displayed drawing.

to the report

Customer Success Story

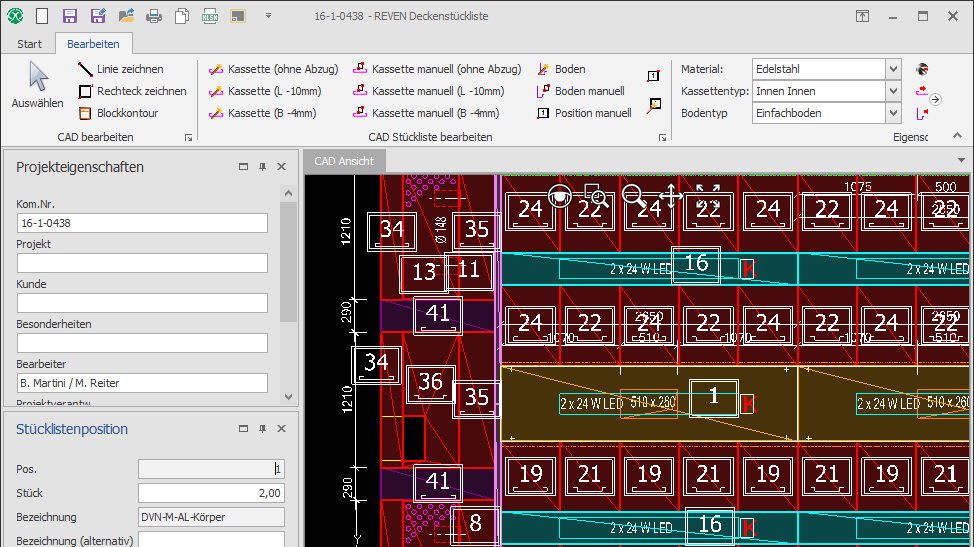

REVEN Bill of Materials

The manual creation of a parts list for a ventilated ceiling was a time-consuming task at Rentschler REVEN. Dimensions had to be read off the drawing or measured, the item numbers had to be rewritten on the paper when the drawing was changed. In order to speed this up and also to obtain a more professional appearance, a programme was created for this special application that can create and manage a parts list semi-automatically on the basis of the DWG file.

to the report

Customer Success Story

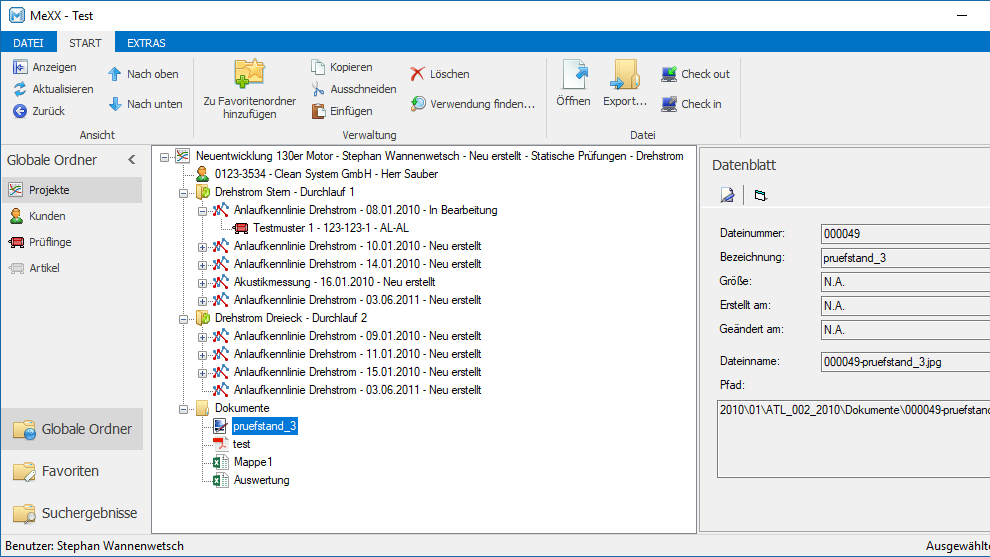

MeXX

The company Robert BOSCH GmbH in Schwieberdingen uses the MeXX measurement data management system to manage all test data generated in the product development process. Read the reference report to find out how they keep track of the data generated by around 200 tests on over 1,000 valves a year.

to the report