User report as PDF

Download the user report as a PDF file

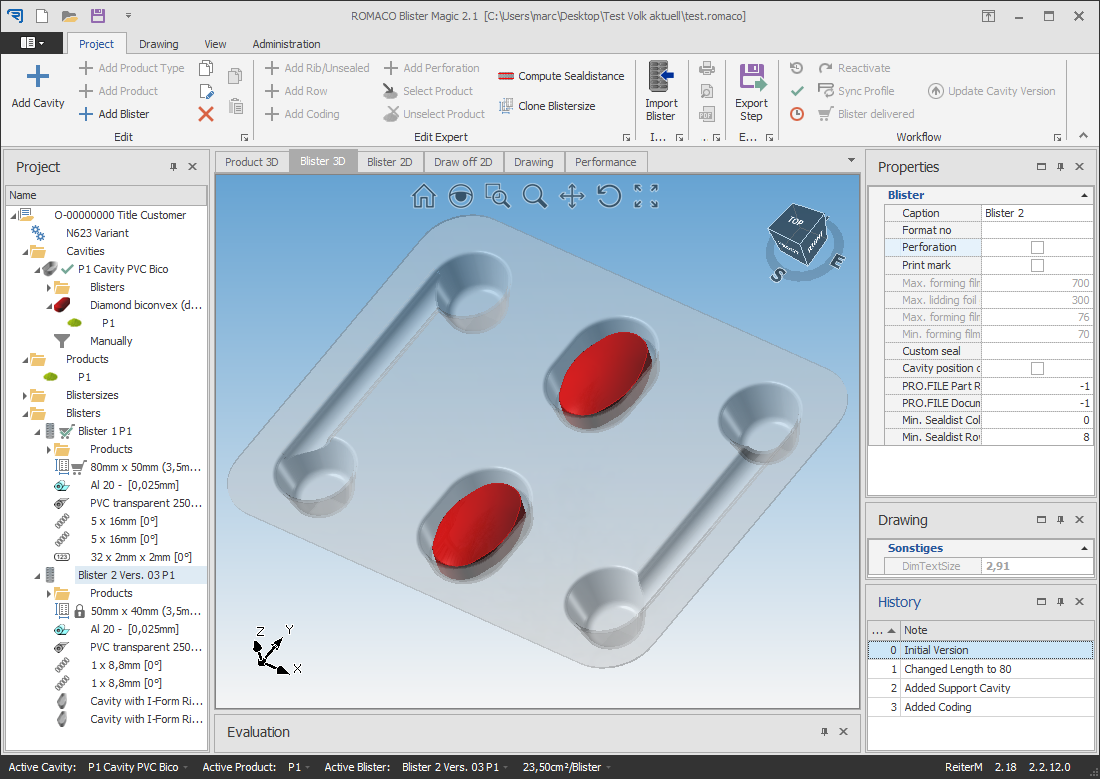

REITEC develops blister pack design software for ROMACO

The design of blister packaging is a key element of ROMACO's machine and tool distribution activities. With the help of the CAD System ME10 and a dedicated auxiliary software, 2-D representations of the blister packs were created in the back office.

Because the auxiliary software was only operable in combination with the CAD system, it was often not available when the sales agents were at their customers' sites. The latter could hardly gain a proper impression of the finished blister packs from the 2-D representations. The employees could not see in the system which blister formats had already been projected for a specific machine. They were required to enter all data once more when setting up a new blister pack in the PDM system.

The idea of developing a CAD-independent software that would run on any Windows-based PC was born. The software should contain all blister formats of the customer for the packer to be used and should support easy reuse of previous designs. After the design of the blister, the drawing should be created automatically to the greatest possible extent and the user should be able to store the drawing together with the corresponding data in the PDM system by pressing a single button. The calculation rules and the design method should be taken over from the software currently in use.

REITEC GmbH developed the software “Blister Magic 2“, which contains complete 2-D and 3-D environments for the representation of the product, the cavity and the blister. An environment for the creation of drawings offers comprehensive editing options to the user.

All pertaining elements are linked in an associative manner. When the user changes a parameter, the representation is updated immediately. A wizard supports the user in the creation of a blister. The user can edit the blister subsequently with the help of the mouse or by changing parameters as in the CAD system. Release management and change control have been fully

R. Izsak, Head of Project Engineering at ROMACO Pharmatechnik GmbH aptly describes the situation asfollows: “The new software by REITEC is a very powerful tool that supports us optimally in our daily work. ”The easy manipulation of this customizable software that runs independently of any CAD system provides for a high productivity. The configuration options allow the user to quickly react to new requirements. The appealing representation in the drawing creates added value to the customer.

Romaco is among the world's leading special vendors of process and packing technology for the pharmaceutical industry. The company, which is divided into the three branches processing, tableting and packaging, develops engineering and system solutions for the pharmaceutical sector and supplies the markets of cosmetics, food and chemical applications. The Romaco Group, which has its headquarters in Karlsruhe (Germany), sells seven different brands of cross-sectorial products at four sites in Europe. The packing technologies for Noack, Siebler, Bosspak, Macofar and Promatic are manufactured in Karlsruhe(Germany) and Bologna (Italy). The Cologne-based company Kilian supplies tableting equipment. The Innojetproduct line, produced in the German town of Steinen, is suitable for granulation and coating applications. The product portfolio of this full-range supplier includes primary, secondary and final packaging solutions, aseptic and non-aseptic liquid and powder filling equipment, tableting, granulating and coating applications. Currently, more than 12.000 machines manufactured by ROMACO are in use in over 180 different countries. About 550 highly qualified and committed employees take care of the group's customers all over the world.

Download the user report as a PDF file