User report as PDF

Download the user report as a PDF file

Optimised measurement data management at Bosch Gasoline Systems

Product development benefits from standardised structures

In the Gasoline Systems division of Robert Bosch GmbH, the competencies for the entire powertrain are brought together under one roof - in the spirit of ultra-modern, environmentally conscious vehicle development. The GS-DI department of Bosch Gasoline Systems develops injection valves for fuel-efficient and low-emission gasoline engines. In the course of product development, the valves are subjected to numerous tests in standardised procedures.

The amount of data generated in terms of measured values, characteristic curves, image data and detailed information is considerable: around 200 tests on more than 1,000 valves are on the programme every year. The determined data as well as supplementary test bench templates and test reports were previously stored and managed in a folder structure in the file system. What was missing in the existing system for the optimal evaluation and further utilisation of the recorded measurement data and information were, among other things, cross-references, additional information and a search system that was as effective as possible for retrieving relevant data. Against this background, the aim was to optimise the storage and administration of data and the associated work processes with a new programme. At the same time, the solution should be able to be integrated into the existing IT systems without major effort.

In view of the high number of items examined in the GS-DI department year after year, a considerable potential for improvement through effective data handling was obvious, especially in the area of test item management. The concrete requirement for the new system: test item data should be generated automatically, i.e. immediately retrievable, and thus replace the time-consuming manual creation of individual test item data records. In addition, the test specimens should be recognised by means of a data matrix code and be able to be processed by the system.

Bosch decided to implement the MeXX measurement data management programme from Reitec. Already during the realisation of a simple test environment, the programme proves its efficiency by offering - defined in the standard - flexible solution approaches for the most diverse problems.

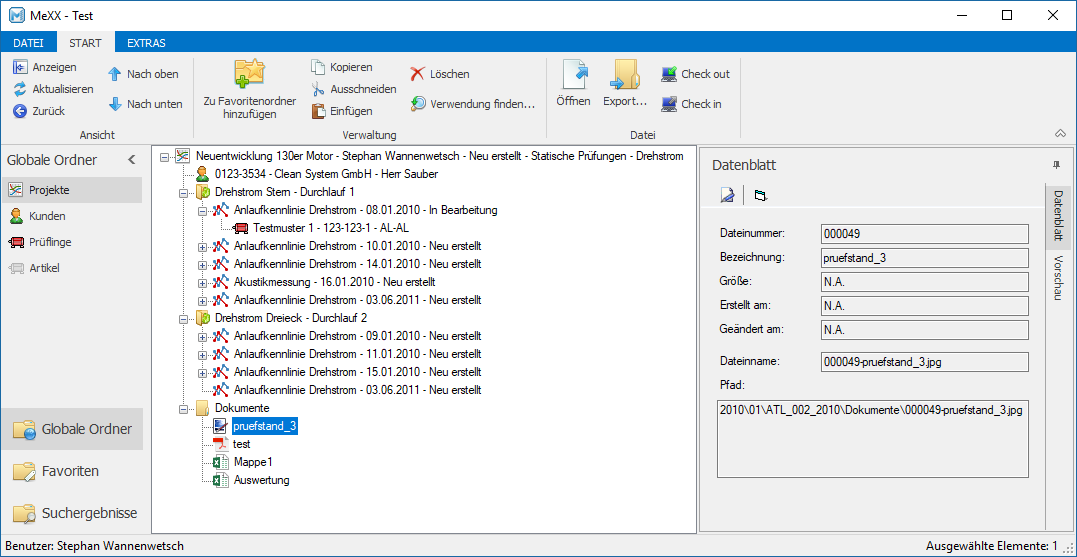

The central tree structure shows the relationships of the data directly and clearly. In combination with the search functions, this results in a range of options for data retrieval that was previously not possible at Bosch Gasoline Systems. For example, the new system at Bosch allows the user to search for all tests for a specific valve test specimen. Further options such as the automated test item management with connection to the production database of the prototype shop as well as the integration of a completely revised assistant for the creation of measurement templates on an Excel basis could be integrated without any problems thanks to the sophisticated modular structure of MeXX and can be called up directly from the programme. In addition, important information for quality assurance and certification, such as the test stand used, the software used or the relevant parameter set, is available directly and in a user-friendly manner. The system also provides direct access to the test item history, which virtually maps the life of each test item. It is a standard feature of MeXX.

The system, which was implemented in October 2008 and is based on the MeXX management programme, has so far achieved top marks in the day-to-day operations of the GS-DI department at Bosch Gasoline Systems. In particular, it convinces with its seamless integration into existing processes and high efficiency in everyday operations. According to the employees, the flexibility of the almost freely configurable programme, even in the standard version, as well as the adaptability of the modular and expandable system, which makes subsequent additions possible without any problems, have also proven their worth. The users' summary: "Today, MeXX is the control centre of our product development. The programme offers valuable support for our daily work and has opened up completely new perspectives with regard to our extensive data material."

The Bosch Group is a leading international technology and services company. With automotive and industrial technology as well as consumer goods and building technology, some 280,000 associates generated sales of 45.1 billion euros in fiscal 2008. Automotive Technology is the largest business sector in the Bosch Group. With 168,571 employees, it generated sales of 26.5 billion euros in 2008.

Download the user report as a PDF file