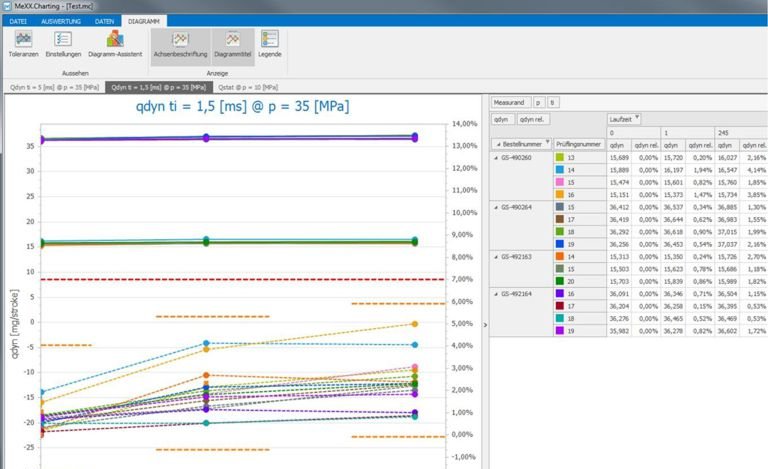

Automated evaluation and analysis

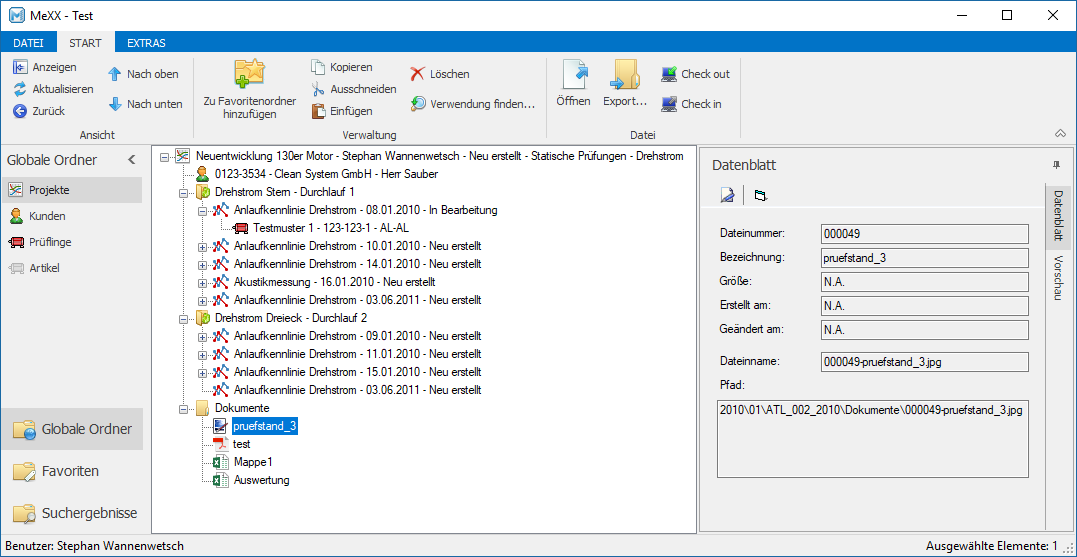

MeXX offers a comprehensive diagram module with pivot functionality for evaluating the stored data. Standardised, recurring reports can be generated automatically with a few clicks via the template function. Image data from imaging procedures can be directly analysed and processed.